A recurring question in crossover tuning is determining the actual edge lift of the shim stack and the shock shaft velocity where crossover gaps close.

Dyno tuners have developed a method to estimate deflection of the stack face shim by installing a stiff backing plate behind the shim stack. When the face shims hit the backer the damping force kicks up giving a measure of the shaft velocity needed to deflect the shim stack.

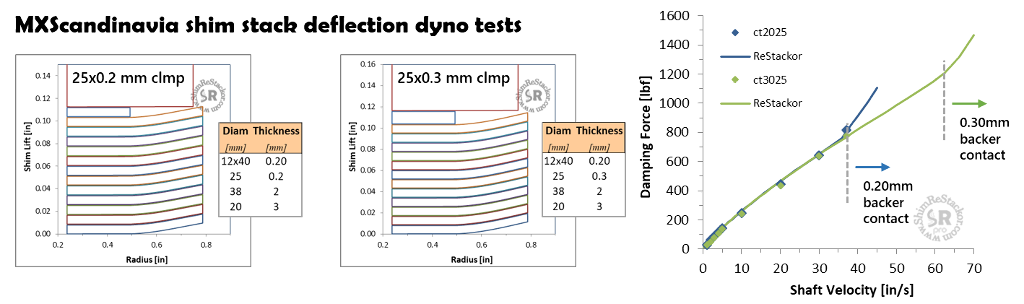

MXScandinavia shows an example of the dyno test technique on Thumper Talk.

The dyno data shows a shaft speed of 35 in/sec closes the 0.20 mm gap (data points). Retesting with a larger 0.30 mm gap requires nearly double the shaft velocity (lines computed by Shim ReStackor). MXScandinavia’s dyno could not produce the shaft speed and 1200 lbs of force needed to close the larger crossover gap.

Separate dyno tests run with a backing plate estimate shim stack deflection and closure of crossover gaps

Damping curve shape control

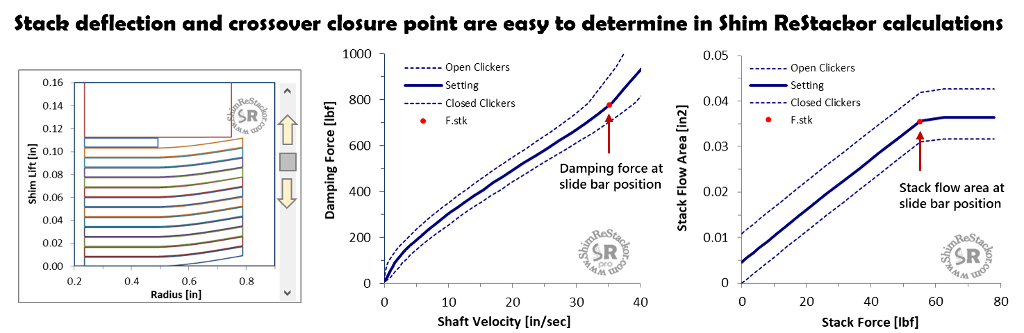

Determining deflection of the face shims and closure of crossover gaps is much easier with Shim ReStackor. The Shim ReStackor weight scaling spreadsheets include a slide bar on the shim stack deflection plot. Moving the slide bar pans the shim stack through the computed deflection range and positions the “F.stk” marker on each plot showing the value at that shim stack deflection.

Finding the crossover closure velocity simply requires dragging the slide bar around to close the gap on the shim stack plot. In this case a shaft velocity of 35 in/sec is needed which was verified by MXScandinavia dyno data.

Shim ReStackor plots of edge lift and shim stack flow area identify crossover gap closure velocity