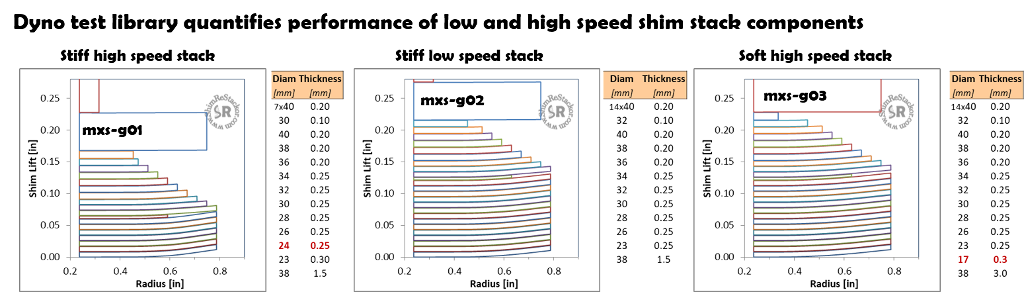

A recurring theme in dyno testing is the idea of developing a dyno test library archiving performance of low and high speed shim stack. With the library, components of the shim stack could be mixed and matched to create any damping force profile needed.

A thread on Thumper Talk outlines the process and proposed three shim stack configurations spanning the range of tuning:

- g02: Baseline setup with balanced low and high speed damping

- g01: Rough track setup. Softer low speed stack to improve ground compliance and an additional shim in the high speed stack to give the required bottomin resistance needed for rough tracks

- g03: Groomed track setup. Baseline low speed stack to preserve chassis control and softer high speed for groomed track operation

Proposed shim stack configurations to handle wide range of MX track conditions

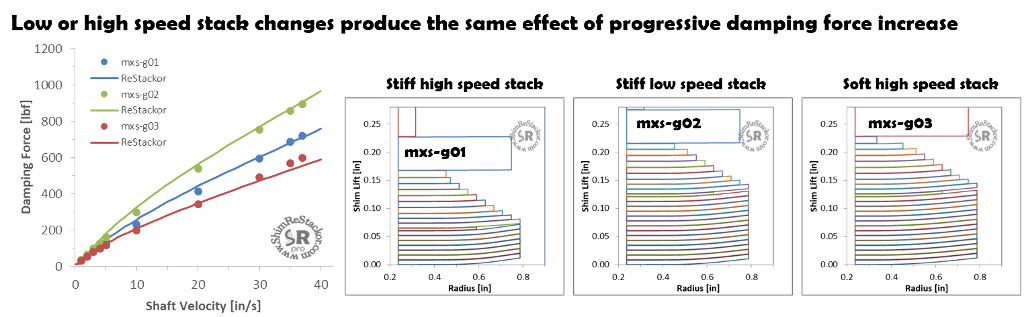

Dyno library test results

MXScandinavia dyno tested the three configurations....

Dyno test results

The proposed configurations make no difference in high or low speed damping. All three shim stacks follow the same damping force curve and are simply stiffer or softer. MXScandinavia knew that, but dyno tested the shim stacks anyway.

Changes to the high or low speed stack make little difference in high or low speed damping. Dyno tests have demonstrated that over and over again. But the myth still persists.

Proposed changes to high and low speed stack make no difference in high and low speed damping

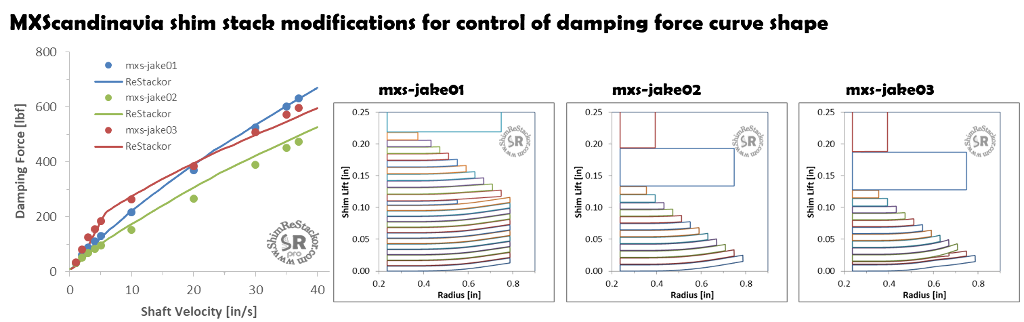

Damping curve shape tuning

MXSCandinavia went on in the thread to demonstrate the shim stack modifications needed to gain separate control of high and low speed damping:

- Preloading a soft shim stack increases damping force at low speed and softens damping force at high speed

- A crossover does the opposite with softer low speed and stiffer high speed

- A soft tapered shim stack matches the crossover stack at low speed and drops off at high speed

Each of those shim stack configurations is completely different. There is no mixing and matching of shim stack components drug out of a dyno test library. Each configuration is unique.

Tuning to get the desired damping force curve shape is simply done by hacking: adding or removing shim stack preload and crossovers to get the desired damping force curve shape and hacking around on stiffness to get the desired damping force value.

The numerical test bed of Shim ReStackor makes that simple, easy and intuitive.

Shim stack preload, crossovers and stack stiffness control damping force curve shape